1942 SCHRADER

U.S. NAVY MK V DIVING HELMET

US Navy Inspection Stamp

& Matching Numbers

Schrader was one of the original maker’s of Navy

MK V’s during WW II. Owned for the last 42 years by single party!

TOTAL WEIGHT:

53 lbs BONNET: 31 lbs BREAST PLATE: 22 lbs

SERIAL NUMBER: 427 A

DATE: Aug – 1942

STAND

NOT INCLUDED

Copyright 2014 by Land And Sea Collection™, All Rights Reserved

Presented

is a high quality U.S. Navy MK V helmet made by Schrader in 1942. It has just come on the market because of a family illness. It

was purchased by the most recent owner in April, 1972, from the Salmons Dredging

Company of Charleston, SC, who had acquired it from the Navy where it had been in service at the Charleston Navy

Ship Yard. This Navy Yard operated from 1901 as a dry dock,

and continued as a navy facility until 1996, when it ceased operations due to the 1993 Base Realignment and Closure

Commission Act. During that period, it repaired and built warships and serviced submarines.

Salmons

Dredging Corporation was founded in 1919 to provide dredging and marine contracting services and continues in business

today. Over its 95 year history, the company has evolved into a general heavy marine construction company, and has been owned

and managed by the family. Salmons Dredging Corporation, headquartered in Charleston, specializes in marine construction

and provides commercial diving, marine services, and marine terminal operations to the industrial, transportation, government,

utility, and service sectors in the southeastern United States.

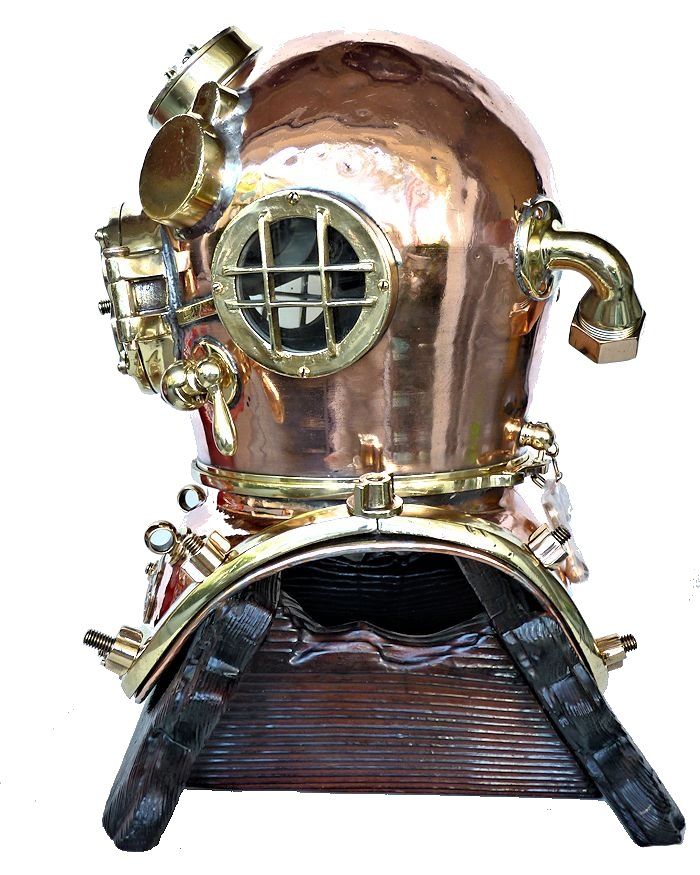

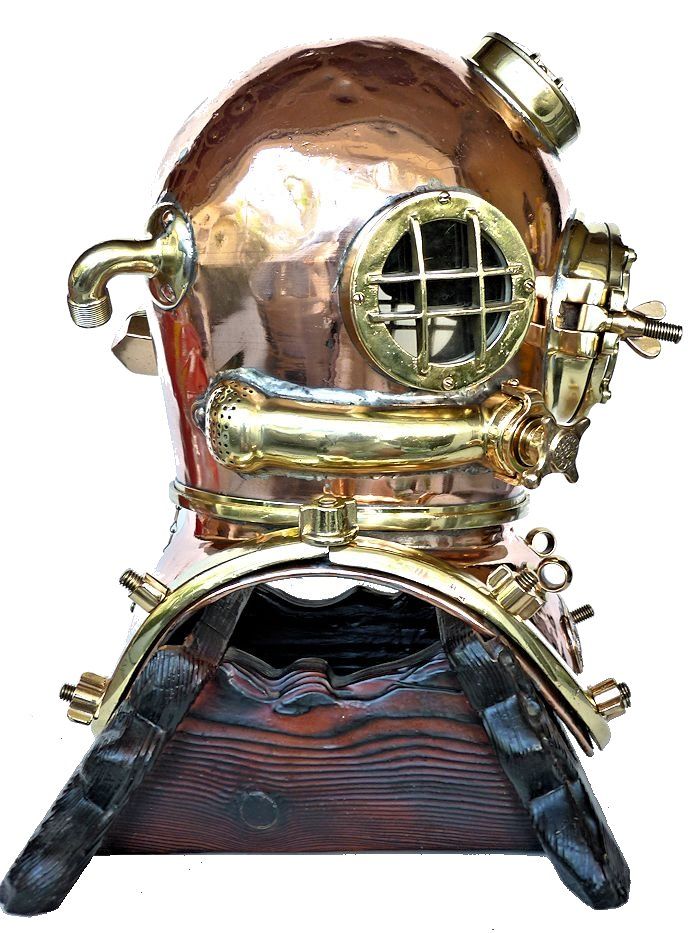

HELMET

& MARKINGS: Authentic 12 bolt, 4 light Schrader Navy MK V dated AUG 1942 with serial number 427 A on

the maker’s tag. The bonnet is stamped 427 on the welder’s

attachment bracket between the front port housing and the left side port. All

the brails are marked 427 A . There is the Navy Inspectors mark of a “U anchor S” on the top of the speaker

housing’s stub.

Maker’s

tag/ Inspectors’s stamp/ Bonnet’s serial numberCONDITION:

Considering its 72 year age and Navy and Commercial use, it is in very good condition overall. There are

numerous small dents and abrasions all over the bonnet showing its years of use, and the dumbbell lock is broken

off at point of attachment. A new DESCO replacement dumbbell comes with the helmet and is shown in pictures of the back of

the helmet. The front door hinge pin is original. As received

by us about 10% of the original tinning on the bonnet remains and about 50% of the tinning on the breast plate was worn

off. The mottled appearance did not show well so it was recently polished and lacquered. The breast plate neck

ring gasket is broken into four segments, but functions. The

air vents are all intact. The right side chin relief valve, spit cock handle, front door wing nut, all turn easily. The

internal spring to the exhaust valve is missing. There is a very slight crease under the lower neck ring from side to

side that many people would not notice. The speaker housing is empty. No check valve is fitted, and the

comm elbow has a nut. =left>

Left

and Right side of the helmet. The stand is NOT INCLUDED!Like all used diving gear, this is being sold for DISPLAY ONLY. It should not be dived without having passed

inspection by a certified dive shop.

|

The back of the helmet shows broken and the DESCO replacement dumbbell and rivet |

|

| View showing the BTE gate valve and the bannana exhaust |

HISTORY OF SCHRADER DIVING:

Schrader is one of the oldest names in U.S. diving, second only to Morse. The founder, August Schrader was a creative and

inventive German immigrant who originally set up a shop dealing in rubber products in New York City, NY in 1839, only a few years after A.J. Morse

set up shop in Boston =left>.=left>=left>

In

1845 he began supplying fittings and valves for rubber products made by the Goodyear Brothers. Schrader was also a maker

of daguerreotype apparatus. His original shop was at 115 John Street =left>in Manhattan, NY =left>. Shortly thereafter he went into partnership with Christian Baecher. Christian

was a brass turner and finisher which provided a foundation for what followed.=left>=left>

The

two partners, having watched divers at work at a nearby New York Harbor jetty, decided to improve the diving helmets

in use at the time. In 1849, with the help of Baecher, he created a new copper helmet. Later his interest in diving led to

him to design an air pump.

Around

1890, August Schrader saw the need for a bicycle tire valve. By 1891, he produced the Schrader valve. The Schrader valve was

his most popular invention, and is still used today.

In

1917, the United States Bureau of Construction & Repair introduced the MK V helmet and dress, which then became the standard

for US Navy diving until the introduction of the MK 12 in the late nineteen seventies. Schrader and Morse Diving were

the two original suppliers.

During

the onslaught of World War Two only Morse and Schrader were making dive helmets for the navy. DESCO and Miller-Dunn went

into production around 1943. In total only about 7,000 MK V helmets were produced by all four companies during the war years

with DESCO producing the most, then Morse, Schrader and Miller-Dunn. The scarcity of the latter two are the reason they command

a higher price in the market.

BRIEF

HISTORY of NAVY MK V DEEP SEA DIVING DRESS:

By

1915, the Bureau of Construction and Repair had designed the MK V Diving Helmet which seemed to address many of the problems

encountered in diving. This deep-sea outfit was designed for extensive, rugged diving work and provided the diver maximum

physical protection and some maneuverability.

The

1915 MK V Diving Helmet had an elbow inlet with a safety valve that allowed air to enter the helmet, but not to escape back

up the umbilical if the air supply were interrupted. Air was expelled from the helmet through an exhaust valve on the right

side, below the port. The exhaust valve was vented toward the rear of the helmet to prevent escaping bubbles from interfering

with the diver’s field of vision.

By

1916, several improvements had been made to the helmet, including a rudimentary communications system via a telephone cable

and a regulating valve operated by an interior push button. The regulating valve allowed some control of the atmospheric pressure.

A supplementary relief valve, known as the spitcock, was added to the left side of the helmet. A safety catch was also incorporated

to keep the helmet attached to the breast plate. The exhaust valve and the communications system were improved by 1927, and

the weight of the helmet was decreased to be more comfortable for the diver.

After

1927, the MK V changed very little. It remained basically the same helmet used in salvage operations of the USS S-51 and USS

S-4 in the mid-1920s. With its associated deep-sea dress and umbilical, the MK V was used for all submarine rescue and salvage

work undertaken in peacetime and practically all salvage work undertaken during World War II. The MK V Diving Helmet was the

standard U.S. Navy diving equipment until succeeded by the MK 12 Surface-Supplied Diving helmet in February 1980, which

in turn was replaced by the MK 21 in December 1993.